We’ll be the first ones to agree with you, last season was incredible. Colorado (among many other western US states) received record setting snowfall which made for great early season snow, a plethora of mid-winter pow days, and stable late season conditions. Maybe it was the snow, or maybe was the capital we invested in new presses, staff, and finish machinery, but we managed to again churn out more custom skis than we ever have before. This time by an even bigger margin than the year before.

When the warmer weather finally rolled in, we came up for a quick breath and then put our heads back down to take a hard look at how we can further improve our product quality, production efficiency, and accessibility to you the customer. We’ve taken the summer and fall to fine tune all of this, and are ready to turn the custom ski game on it’s head…

We were going to save this until the end by why delay the inevitable…

What is probably our biggest news to share, is that we’re opening our first ever dedicated Sales Office and Showroom in the heart of Aspen, CO – our home away from home. We do a huge amount of business in the Aspen valley as it is, so when an opportunity came up to run a short term popup location downtown, it was an absolute no-brainer.

Starting in November of 2019, Folsom Custom Skis will have a small custom fit center and retail space based at the Hub of Aspen. There will be prebuilt skis for sale in our standard “Signature Series” construction, as well as opportunities to demo Folsom Skis any day of the week (no more waiting until the once-a-month demo weekend).

Custom Fit Consultations will be a full service option at our Aspen location as well, and custom builds that come through that channel are eligible for a whopping two-day turnaround time. That’s right, custom skis ordered and delivered to Aspen in just two days. We are proud to be the only custom ski manufacturer in the world running a program like this, and are excited to be changing the custom ski game for the better.

After the Spar 88 grew to be our best selling shape, we added to the Spar family a narrower offering. New for the 19-20 season is the Spar 78, our most precise geometry to date. Said Folsom President Mike McCabe, “we used an extra large stringer of uni-directional carbon through the tail of the skis which provides an unreal amount of load and release, resulting in a highly energized pop exiting the turn. The multi-radial tip and tail designs also allow this ski to have a large variety of turn shapes. Light edge pressure creates longer GS turns, while increased edge pressure bends the ski into a snappy slalom style turn shape.”

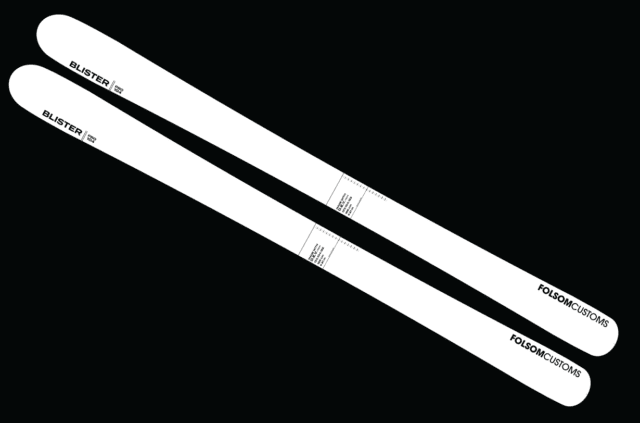

Finally after numerous iterations working alongside the rigorous ski testers at BLISTER, we’re excited to have the build specs and geometry dialed in for Folsom’s BLISTER Pro which is now available for purchase in limited quantity. The R&D started last spring, and throughout the last 6 months we’ve altered flex patterns, rocker heights, and tip tapers to achieve what BLISTER calls “a ski that would work as a strong, versatile, and stable daily driver for places with an abundance of steep, tight, and technical terrain (like Crested Butte), in everything from decent conditions to difficult conditions.”

The BLISTER Pro is available now for order in its standard build spec, or if you’d like to experience the same geometry with slightly different construction (eg. reverse camber, softer flex, etc.), the shape can be fully customized under what we’re calling the Primary 104. Fill out a custom fit form to chat with us further on a custom build on this shape. You can also listen to the full podcast below produced by BLISTER to hear the backstory on how the shape was developed and some bits about our Aspen storefront as well…

And last but not least, with the addition of our new ski press (more on that later), we are able to press skis down to a 135cm length. So after a few dozen requests per year for a youth ski, we figured we’d finally make it happen and have just finished the prototyping for our all new junior shape, dubbed the Hayden. Stay tuned for a product page and more info on this shape coming soon…

Last year only 67% of the skis we entered into FREESKIER Magazine’s annual ski test received Editor’s Picks, that wasn’t good enough for us. So we went back with new and improved geometries and construction styles, and won Editor’s Picks on every ski we entered. That means 100%. In absolutely all-time snow conditions, ski testers destroyed the slopes of Aspen Mountain in March of 2019, enjoying our Completo, Gambit 113, Trophy, Primary, and TRN TEK.

Most notably, was the Gambit 113 (all new for the 18-19 season) which placed 2nd in a heavy hitting group of 100-114mm underfoot freeride skis. Additionally in a #2 spot of its own was our Trophy which snagged silver as well in the 115mm+ Freestyle category, getting praise from testers like, “11/10… would ski again”. Even the TRN TEK placed 9th out of 15 skis in the narrowest of three freeride categories – not bad for a pair of straight skis!

To support the Aspen buildout and offerings, we’ve hired additional staff and beefed up the machinery in our shop significantly. To compliment the standalone stone grinder we bought last year, we’ve invested in standalone belt sander to keep our skis as tuned as we can as they leave the shop – flatter than they’ve ever been. We also designed and built from scratch a brand new wood core press which (1) allows us to press five core blocks at a time (instead of two), but more importantly (2) freed up our third ski press which has been fully converted and is actively functioning as our first dual-bay cassette, meaning we press two skis at a time instead of one. Press 3 (as we call it) is capable of pressing skis down to about 135cm which is about 20cm shorter than we were able to press skis in years past.

With all of this plus nearly doubling our full-time staff, we’re feeling prepped and ready for another kickass season of quality American craftsmanship. Are you?